At our company, we use many advanced machines to make metal parts that are strong and exact. One of the most important machines is called a CNC sheet metal laser cutter. It helps us cut metal sheets very quickly and with great accuracy. I want to explain what CNC laser cutting is, how it works, and why it is so useful for making metal parts.

CNC means Computer Numerical Control. This means a computer controls the machine. Instead of cutting metal by hand, we program the machine with a design on the computer. The machine then follows this design perfectly every time. This helps us avoid mistakes that happen with hand cutting.

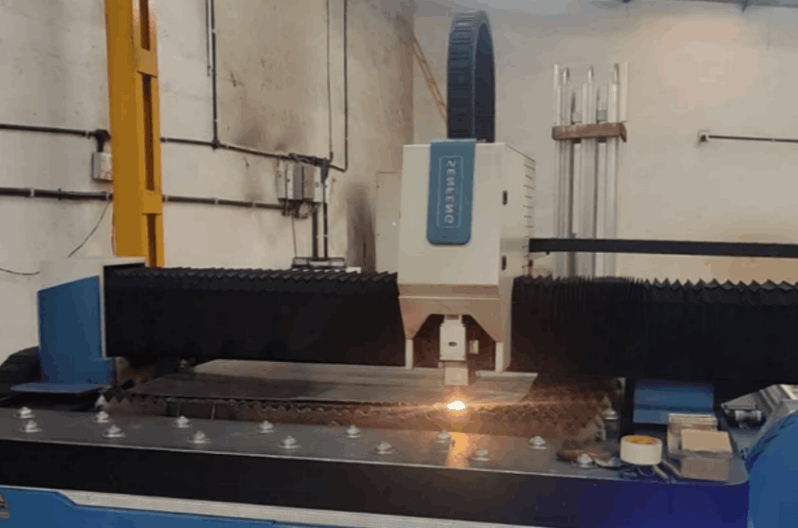

Laser cutting uses a very powerful and focused beam of light called a laser to cut through metal sheets. The laser beam melts or burns the metal exactly where we want to cut. This makes very clean and precise cuts.

Here is how it works step-by-step: First, we create a design on the computer using special software. This design shows the exact shape we want to cut from the metal sheet. Then, we place a flat metal sheet on the machine’s bed. When everything is ready, the computer controls the laser to move along the design and cut the metal. After the laser finishes, we have a metal piece cut exactly in the shape we want.

CNC laser cutting is better than traditional cutting methods for many reasons. One big reason is precision. The laser cuts so accurately that the parts fit together perfectly when assembled. It is also very fast, so we can make more parts in less time, helping customers get their orders sooner. Another great thing is that the laser does not touch the metal directly, so there is less chance that the metal will bend or get damaged. Plus, the edges cut by laser are very smooth and clean, often needing little or no extra work after cutting.

We can cut many types of metals with laser cutting, like steel, stainless steel, aluminum, and copper. Each metal needs the right amount of laser power and speed so the cut is perfect without wasting material.

CNC laser cutting is used in many industries. For example, it helps make car parts, building materials, machine components, furniture, and even parts for electronic devices. At our company, we use laser cutting to make precise parts for all these industries.

In short, CNC sheet metal laser cutting is an amazing technology that helps us make high-quality metal parts fast and accurately. It saves time, reduces waste, and lets us deliver the best products to our customers.

If you want to learn more about our laser cutting services or need custom metal parts, feel free to contact us. We will be happy to help you.

Satish Jain

Engineer and Proprietor

GKH ENGINEERING SOLUTIONS